One garbage truck per second is the speed it takes to dump textiles into the landfill. A reference used by the Ellen MacArthur Foundation expressing the equivalence of how each year millions of tons of clothes are produced, worn, and thrown away, resulting in every second a truck load of clothes is burned or buried in the landfill.

What are the industry’s plans to keep textile waste out of the landfill?

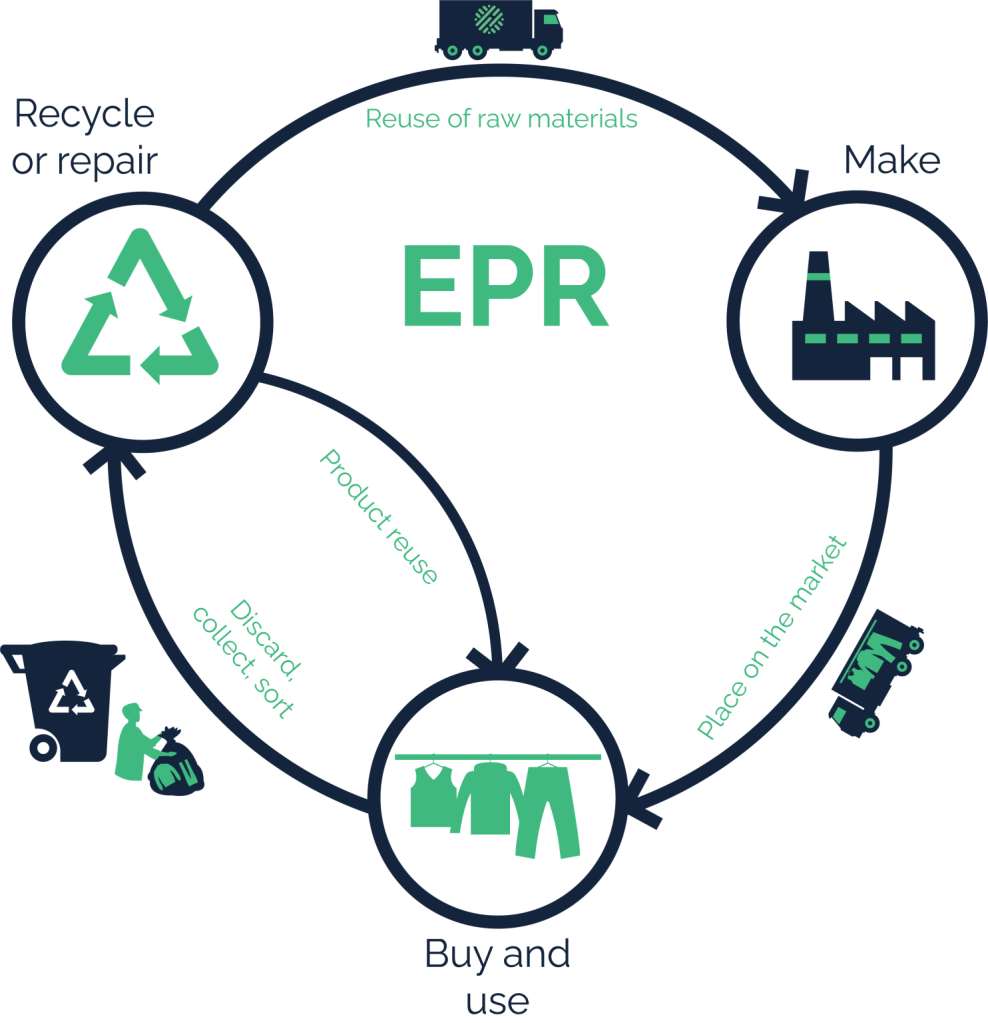

Textile waste is an inevitable outcome of the linear fashion system. To transition to a closed-loop system, the industry must implement effective tools and processes that enhance reuse, recycling, resale, and waste reduction across the supply chain. Two transformative concepts, Reverse Logistics (RL) and Extended Producer Responsibility (EPR), fundamentally redefine our approach to post-consumer waste by recognizing its potential for recycling. As policies, they are essential for establishing the robust infrastructure we desperately need today, focusing on ‘take-back’ collection and waste management systems at their core.

Building an infrastructure to recycle textile waste presents significant challenges, as highlighted by Anjali Krishnan, the Program Manager for IDH Alternate Materials in India. In her interview with the Ellen MacArthur Foundation on The Circular Economy Show podcast, she stated, “Recycling is not easy … reusing is better. It takes money to build infrastructure to collect, sort, reuse, and recycle … Producers, brands, and retailers’ financial contributions to the infrastructure … are attached to a fee … to manage …. This issue needs to be solved internationally.”

To put into scope the scale of managing textile waste, according to Krishnan, India has 45 million people working in the textile industry, 4 million are focused specifically on textile waste management.

Global Fashion Agenda, supported by its Insight Partner, Maersk, released a report, Reverse Logistics for Circular Fashion Systems, that expands on how fashion brands, retailers, value chain partners, and logistics providers can efficiently manage the reverse flow of materials and products from end-users, reintegrating them back into the supply chain for repair, resale, remake or recycling to generate new product. To reclaim a product’s end-of-life, the report highlights the critical role of logistics in supporting fashion companies to adopt a circular system.

EPR and RL, A Deeper Dive

Extended Producer Responsibility (EPR) is a mandatory, fee-based policy that makes producers responsible for their products along the entire lifecycle, including at the post-consumer stage. EPR also creates transparency and traceability on global material flows.

EPR is an essential tool to build an infrastructure that effectively collects, sorts, and processes waste materials for new raw material production. It shifts the burden of textile waste management from municipalities to producers. “EPR is bringing an informal operation into a formalized system. It incentivizes a circular economy at large—producing clothes that last longer”, asserts Krishnan. “A producer or brand will pay a little less or nothing at all if the supply chain puts less products in the masses … in a linear way.”

Reverse Logistics (RL) is the physical movement and management of collecting textile waste from consumers, transporting it back through the supply chain, extending the life of a product through repair, remake, recycle, or to be sorted and reprocessed.

Global Policies and Regulations

EPR Policies and Regulations are either adopted into law, exist in draft form, or are proposed, and it varies by country.

In Chille, EPR is a framework law … a participatory process, we’re a study space right now. – Tomás Saieg, Head of the Circular Economy Office in the Ministry of the Environment for Chile

- In 2016, Chile passed Law 20.920 to reduce waste generation and promote its reuse, recycling, and other types of recovery through the establishment of EPR and other waste management instruments. 2023—implementation and enforcement.

- Kenya, The Sustainable Waste Management (Extended Producer Responsibility) Regulations. Extend the responsibility of a producer over a product and its packaging during the life cycle of the product or its packaging. Law took effect May 2025.

- EU—Eco-design for Sustainable Products Regulation—produce more durable, reusable, repairable, recyclable, and energy and resource efficient products.

- France—Anti-Waste Law for a Circular Economy (AGEC Law)—phase out single-use plastic packaging by 2040, extend the life-span of products, establish systems for collecting and recycling textile waste. Final implementation January 2025.

- France—Climate and Resiliency Law. Passed in 2021, this law mandates large fashion companies to provide environmental impact labels on their products, detailing greenhouse gas emissions, water use, and biodiversity impact. It also bans certain claims like “biodegradable” and “environmentally friendly.”

- The Netherlands Extended Producer Responsibility (EPR) policy for textiles: This policy holds producers and importers accountable for collecting, reusing, and recycling textile waste in the Dutch market. Companies must set up systems to manage textile products during their entire lifecycle.

- California—The Climate Corporate Data Accountability Act is the first law in the United States to require textile and apparel companies to report their Scope 3 (value chain) emissions. Law takes effect January 2026.

- California—Responsible Textile Recovery Act, SB 707. Signed into law in late 2024, the legislation introduces California’s first extended producer responsibility (EPR) framework for textiles. Under SB 707, manufacturers are now responsible for overseeing the full lifecycle of their products, from design to end-of-life disposal.

- The New York Fashion Act (NYFSSA) is a proposed law requiring environmental and social due diligence for large fashion companies in New York. It mandates supply chain mapping, greenhouse gas reduction targets, and reporting on water usage. The Act aims to reduce greenwashing through third-party verification of sustainability reports and create a fund for impacted communities.

- New York and California ban certain chemicals used in waterproofed outerwear.

Resources and Further Reading

- Circular Economy and Sustainability of the Clothing and Textile Industry, PubMed Central (PMC) U.S. National Library of Medicine (NLM)

- Kayla Vasarhelyi, The Hidden Damage of Landfills, Environmental Center, Division of Student Affairs, University of Colorado Boulder, 15 April 2021

- Chilean Law 20290, Establishment of a Framework for Waste Management, Extended Producer Responsibility and Recycling, International Energy Agency (IEA), 5 November 2024 (last updated)

- Extended Producer Responsibility policy for textiles to reduce fabric waste, Ellen MacArthur Foundation, 14 June 2024.

- Textile Regulation Hub, Carbonfact

feature photo credit: rawpixel.com